Warehouse Storage & Picking Solutions

Discover Kardex customized solutions for warehouse storage and order picking. Maximize space, reduce errors, and speed up processes with flexible automated storage and retrieval systems designed to improve your warehouse operations.

Warehouse storage and picking depend on speed, accuracy, and space optimization. Challenges like managing inventory efficiently and avoiding picking errors are critical for success. Kardex addresses these issues by offering highly customizable automated solutions that save up to 85% of space, reduce picking errors by up to 99%, and increase order picking speeds. Our systems are scalable and adaptable, designed to fit the unique requirements of your warehouse, ensuring operational excellence.

Features & Benefits

-

Maximized Storage Space

Recover up to 85% of floor space using vertical and high-density storage solutions

-

Increased Picking Accuracy

Reduce picking errors by up to 99%, ensuring smooth and accurate operations

-

Faster Picking Speeds

Boost picking performance, increasing order processing by up to 300%

-

Scalability for Growth

Adapt easily to growing inventory with flexible, modular storage systems

-

Ergonomic Workflows

Improve operator safety and efficiency with goods-to-person solutions that reduce strain

-

Cost Efficiency

Reduce labor costs and operational expenses by automating manual processes

Maximized Storage Space

Recover up to 85% of floor space using vertical and high-density storage solutions

Increased Picking Accuracy

Reduce picking errors by up to 99%, ensuring smooth and accurate operations

Faster Picking Speeds

Boost picking performance, increasing order processing by up to 300%

Scalability for Growth

Adapt easily to growing inventory with flexible, modular storage systems

Ergonomic Workflows

Improve operator safety and efficiency with goods-to-person solutions that reduce strain

Cost Efficiency

Reduce labor costs and operational expenses by automating manual processes

Insights and Customer Success Stories

Custom-Built Solutions for Warehouse Storage and Picking

Whether you're managing small parts, large pallets, or need a high-density storage system optimized for picking, Kardex has you covered. Here’s how we help you achieve optimal results:

Maximized Storage Capacity

Save up to 85% of your floor space by switching to Kardex storage and retrieval solutions. AutoStore™ solutions empowered by Kardex are ideal for storing small parts with high-density bins arranged in a compact cubic grid. For warehouses with varying item sizes, the Vertical Lift Module Kardex Shuttle offers flexible, vertical storage, accommodating goods of varying sizes. For heavy-duty, palletized goods in high-bay warehouses, we provide robust, scalable solutions for maximum storage efficiency.

Improved Picking Accuracy

Achieve up to 99% picking accuracy with Kardex automated goods-to-person systems. AutoStore solutions and the Vertical Buffer Module Kardex Miniload-in-a-Box automatically deliver items directly to the operator, reducing human error and ensuring the right products are picked every time. Integrated software, such as the Kardex Power Pick System, further enhances inventory control and real-time tracking, streamlining the picking process with precision. For larger, palletized goods, our automated stacker cranes and conveyor systems ensure seamless material flow, minimizing bottlenecks and maximizing productivity.

Scalable for Growth

As your inventory and business grow, so can Kardex solutions. AutoStore solutions empowered by Kardex offer a modular design that easily scales by adding more robots and bins, while the Kardex Shuttle and Kardex Miniload-in-a-Box can expand with additional units as needed. Kardex high-bay warehouse solutions handle heavy loads and can scale up to accommodate large inventories. Whatever the demands of your business, Kardex’s solutions are built to grow with you.

Optimized Workforce Utilization

In the face of labor shortages, Kardex helps you maximize your existing workforce without overburdening them. AutoStore solutions automates small parts storage and retrieval, requiring minimal staff. The Kardex Shuttle and Kardex Miniload-in-a-Box reduce walking distances and streamline picking, while the Kardex high-bay warehouses automates heavy pallet handling. This means fewer physical demands on your team, faster processes, and higher productivity—allowing you to do more with less.

Enhanced Ergonomics

Kardex solutions are designed with operator safety and comfort in mind. Goods are delivered directly to the operator at an ergonomic height, whether using AutoStore, the Kardex Shuttle, or Kardex Miniload-in-a-Box. This minimizes the physical strain caused by bending, reaching, or climbing, leading to fewer workplace injuries and a more efficient workflow. With our automated solutions for pallet handling, we also ensure that heavy goods are managed safely without the need for manual lifting.

More Solutions from Kardex

Temperature-controlled Storage

The transportation and storage of goods under temperature-controlled conditions poses strenuous challenges for intralogistics managers. A growing number of goods are temperature-sensitive and require constant storage temperatures. With years of experience working with the pharmaceutical and food & beverage industries, we understand the stringent guidelines companies face and offer temperature-controlled storage to meet these requirements.

Fire Protection

Kardex offers integrated fire protection solutions to help prevent and minimize damage caused by fires in warehouses and storage facilities. These solutions are designed to detect fires early, contain them, and protect the stored goods.

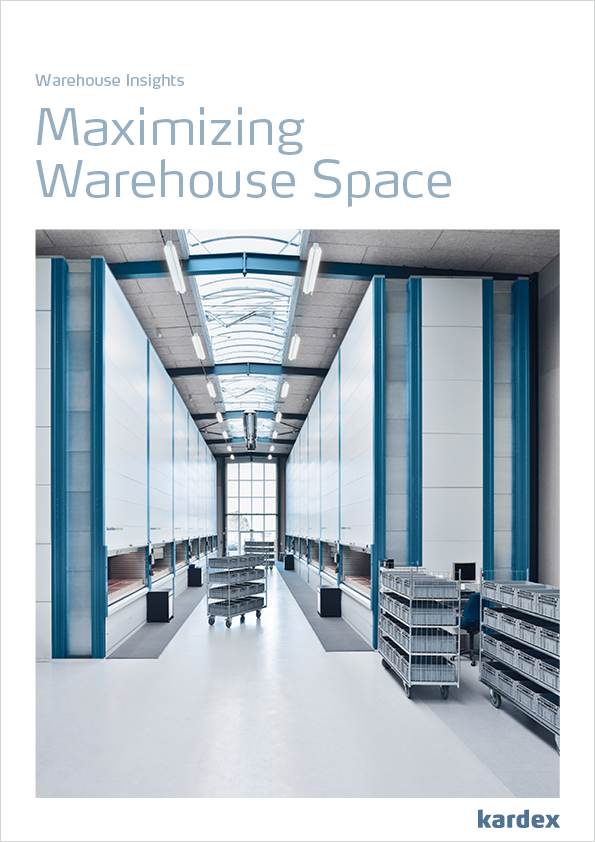

Maximizing Warehouse Space

Facilities using shelving to manage inventory often find themselves squeezed for space. Before you tear down walls to expand or sign a lease for an additional facility, be sure you're maximizing the warehouse space you currently have. Discover how Kardex can help.