Wood Panel & Timber Handling Solutions

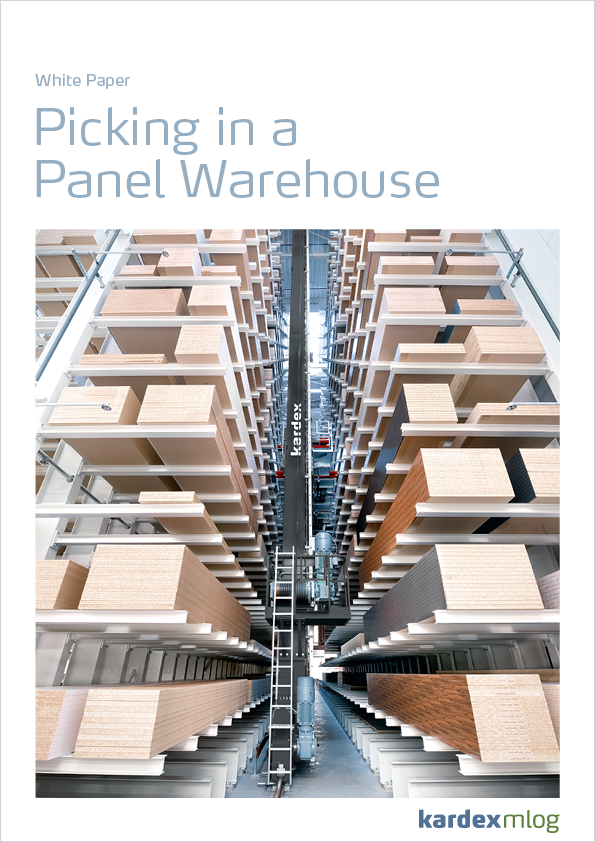

ASRS needs for manufacturers in the timber and wood processing industry include handling large-format worktops, half and full panels, fronts, and body components.

Despite weighing up to 100 kilograms and extending up to 5.60 metres long, these panels must be picked individually, but also stacked safely, quickly, and flawlessly.

Automated solutions with stacker cranes clearly outperform manual concepts with side-loading forklifts or mobile platforms.

Features & Benefits

-

Optimal and Flexible Use of Space

Optimise space for storing kitchen components and accessories in a fully automated high-bay warehouse.

-

Maximum Production Utilisation

Kardex automated storage maximises production capacity by efficiently storing and delivering panels just in time for use.

-

Safe Storage Under Controlled Conditions

Kardex ensures optimal panel protection by preventing fires and maintaining climate consistency, including humidity control.

-

Automated Storage System for Panel Picking

Panels are efficiently picked with a suction traverse and storage machine, forming mixed stacks while protecting surfaces.

-

Transparent and Efficient Processes

Kardex's automated systems enable fast storage and retrieval, with software ensuring accurate stock control and smooth material flow.

-

Lower Labour Costs with Enhanced Efficiency

Kardex's solutions automate labour-intensive tasks, cutting staffing needs and overtime, resulting in cost savings and higher profitability.

Optimal and Flexible Use of Space

Optimise space for storing kitchen components and accessories in a fully automated high-bay warehouse.

Maximum Production Utilisation

Kardex automated storage maximises production capacity by efficiently storing and delivering panels just in time for use.

Safe Storage Under Controlled Conditions

Kardex ensures optimal panel protection by preventing fires and maintaining climate consistency, including humidity control.

Automated Storage System for Panel Picking

Panels are efficiently picked with a suction traverse and storage machine, forming mixed stacks while protecting surfaces.

Transparent and Efficient Processes

Kardex's automated systems enable fast storage and retrieval, with software ensuring accurate stock control and smooth material flow.

Lower Labour Costs with Enhanced Efficiency

Kardex's solutions automate labour-intensive tasks, cutting staffing needs and overtime, resulting in cost savings and higher profitability.

Customer Success Stories

Discover our solution for storing wood panels

Custom-Built Solutions to Fit Your Needs

At Kardex we offer specialised storage and retrieval solutions tailored to the unique needs of the wood panel handling industry. These solutions provide numerous benefits that can optimise operations and enhance efficiency.

-

Full or Half-Format

Dimensions are not defined exactly. The length and width depend on each manufacturer’s production machines. From the manufacturing site, the panels move to retail trade or are processed further – either in their entire length or cut into half-formats. Stacker cranes with side-loading forklifts or mobile picking platforms (common features in retail logistics) convey both sizes. -

Reduced Personnel Costs

One advantage of automation is the significant reduction in personnel costs due to less manual intervention. However, this benefit should always be considered in relation to the higher investment involved in introducing automated systems. Our solutions can be adapted precisely to the company's individual needs and operating processes. -

Significant Space Gain

A not insignificant factor when investing in a fully automated solution is the space required, which is significantly less. In comparison, the usable height remains much more limited with manual solutions such as forklift trucks. -

High Reliability for the Future

With forward-looking planning, companies can adapt their warehouse layout as required and flexibly adjust the dimensions of the stored materials to changing market requirements. In addition, the picking performance of a stacker crane can be quickly adapted to current demand without the need for complex personnel planning, as production planning is controlled directly from the IT system. Furthermore, such warehouses offer a high level of reliability that effectively compensates for technical faults.

More Solutions from Kardex

High-Bay Warehouse

Warehouse Modernisation

With Kardex's individual services for warehouse modernisation, modification, and expansion, we maximise your system's performance and availability into the future.