Automated Solutions for Tires

Despite optimization in the manufacturing process from material procurement to tire construction and vulcanization, significant cost-saving potential remains through the automation of intralogistics along the production line.

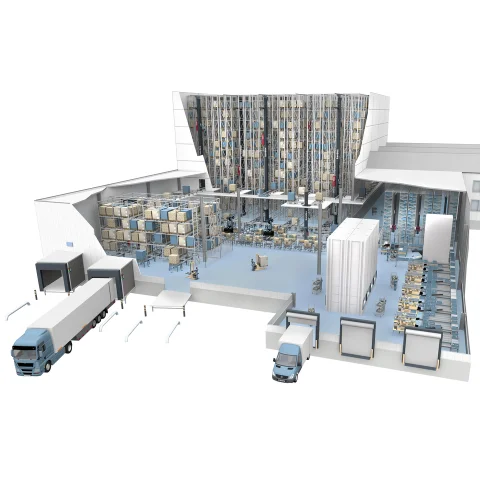

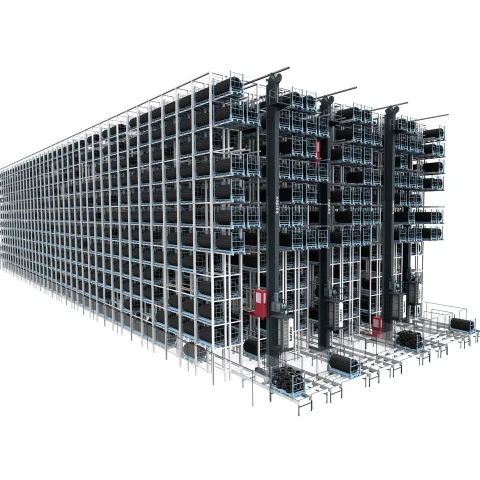

With a comprehensive portfolio and extensive experience across multiple applications, Kardex is a trusted intralogistics partner for the tire industry. Our solutions include automated storage and retrieval systems (ASRS) for pallets with rubber compounds, custom transport carts, green tires, and rack-supported storage systems for finished goods. The choice of components is tailored to the required dynamics and the type and volume of logistics units involved.

Features & Benefits

-

Multiple Processes

Guarantees high process quality of multiple processes at different speeds.

-

Reduced Handling

Our systems reduces the handling steps by 2/3.

-

Space Optimization

Uses space effectively and makes intermediate storage more compact.

-

Data Availability

Provides transparent and consistent data.

-

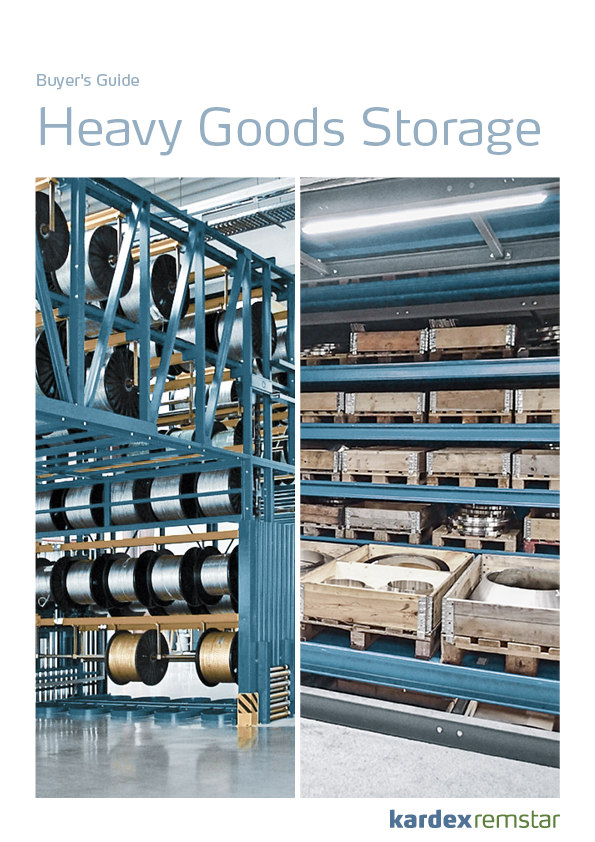

Heavy Load

Allows tire weights up to 180 kg.

-

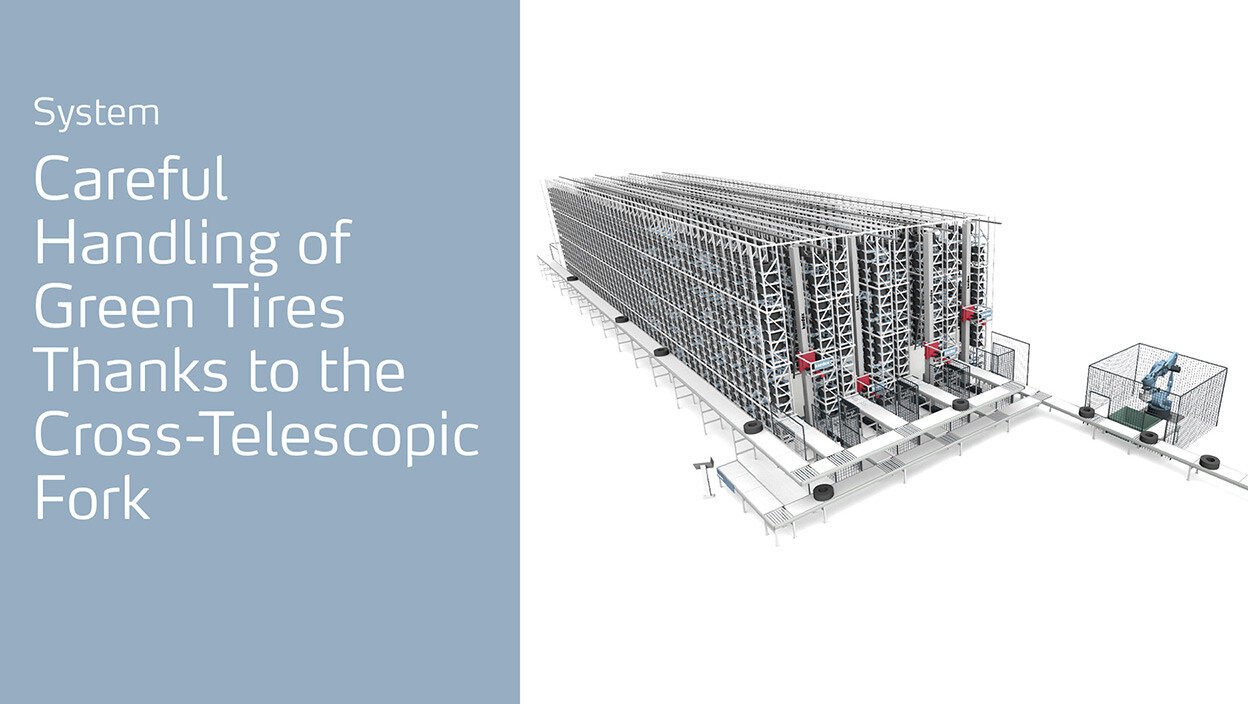

Without Load Carrier

Stores green tires without load carriers.

Multiple Processes

Guarantees high process quality of multiple processes at different speeds.

Reduced Handling

Our systems reduces the handling steps by 2/3.

Space Optimization

Uses space effectively and makes intermediate storage more compact.

Data Availability

Provides transparent and consistent data.

Heavy Load

Allows tire weights up to 180 kg.

Without Load Carrier

Stores green tires without load carriers.

Insights and Customer Success Stories

Creating your tires solution

Custom-Built Solutions to Fit Your Needs

At Kardex we offer specialized storage and retrieval solutions tailored to the unique needs of the tire industry. These solutions provide numerous benefits that can optimize operations and enhance efficiency.

- Error-Free with RFID

High-bay warehouse and extensive conveying technology secure replenishment supplies. - Increased capacity

As a full-service provider, Kardex offers an automated high-bay warehouse for customized customer pallets with extensive conveying technology and overlaid warehouse management software. - Maximum transparency

The article data stored on chips is read on storage and transferred to the Kardex Control Center software, and there it is checked for plausibility against previously received data. Kardex Control Center is a modular warehouse management system, which handles warehouse management and material flow control for raw materials.

By leveraging Kardex solutions, your business can benefit from reduced handling steps, increased capacity, efficiency, and heavy load storage. To explore more about these benefits and the capabilities of Kardex solutions get in touch and start the conversation.

More Solutions from Kardex

High-Bay Warehouse in the Shipping Area