Applications / Spare Parts Management

At Kardex, we understand the importance of reliable spare parts storage. Our innovative solutions are designed to meet the unique needs of different industries, ensuring the safe and efficient storage of sensitive items.

Our spare parts storage solutions offer a range of features and benefits that cater to the unique needs of different industries.

Features & Benefits

-

Reduced Airflow

Reduced air flow minimizing airborne particles

-

Clean Room Airlocks

Keep your packing environment clean from outside particles

-

Pallet Changer

Pallet changer for efficient and hygienic material handling

-

EN-ISO Classifications

Classifications ranging from EN-ISO 5 to 8

-

Exact Temperate Control

Constant temperatures maintained to within +/–1 K

-

Pressure Control

Positive/negative pressure preventing contaminants

Reduced Airflow

Reduced air flow minimizing airborne particles

Clean Room Airlocks

Keep your packing environment clean from outside particles

Pallet Changer

Pallet changer for efficient and hygienic material handling

EN-ISO Classifications

Classifications ranging from EN-ISO 5 to 8

Exact Temperate Control

Constant temperatures maintained to within +/–1 K

Pressure Control

Positive/negative pressure preventing contaminants

Insights and Customer Success Stories

Creating your clean room solution

Partner with an Industry Leading Provider

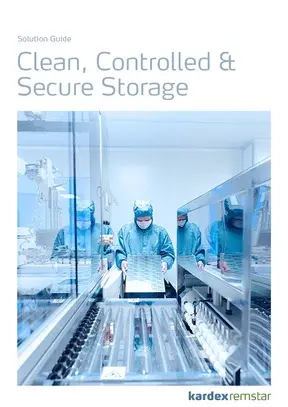

At Kardex, we understand the importance of meticulous storage conditions for industries such as pharmaceuticals, semiconductors, aviation, medical, and optical. Our clean room solutions are designed to meet the stringent requirements of these industries, ensuring the safe and contamination-free storage of sensitive items within specific clean room conditions.

Our clean room solutions offer a range of features and benefits that cater to the unique needs of different industries. Here are some key highlights:

-

Clean room classifications: Kardex clean room solutions adhere to clean room classifications ranging from EN-ISO 5 to 8 (5 on request). These classifications ensure that the storage environment meets the required cleanliness standards for specific industries.

-

Positive/negative pressure: Our clean room solutions can maintain positive or negative pressure within the storage area as per the specific requirements. This helps to prevent the entry of contaminants and maintain a controlled environment.

-

Reduced air flow: To minimize the risk of contamination, our clean room solutions incorporate reduced air flow systems. These systems ensure that the air circulation within the storage area is optimized while minimizing the presence of airborne particles.

-

Clean room airlocks: Kardex clean room solutions include clean room airlocks that act as a buffer zone between different areas with varying cleanliness levels. These airlocks help to maintain the integrity of the clean room environment by preventing the direct transfer of contaminants.

-

Pallet changer: For efficient and hygienic material handling, our clean room solutions can be equipped with a pallet changer. This feature allows for the automatic replacement of load-carrying devices with hygienically safe plastic pallets, ensuring the cleanliness of stored items.

More Solutions from Kardex

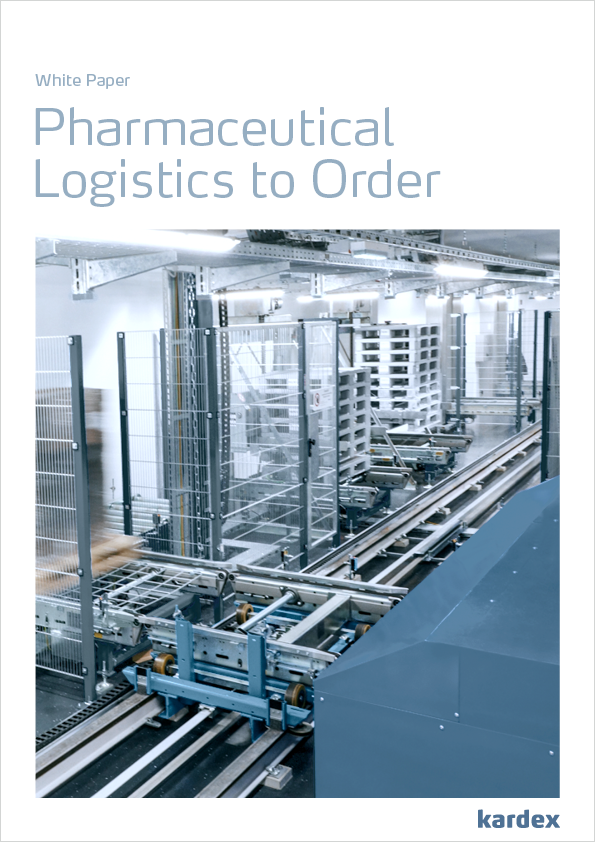

Temperature-controlled Storage

The transportation and storage of goods under temperature-controlled conditions poses strenuous challenges for intralogistics managers. A growing number of goods are temperature-sensitive and require constant storage temperatures. With years of experience working with the pharmaceutical and food & beverage industries, we understand the stringent guidelines companies face and offer temperature-controlled storage to meet these requirements.

Fire Protection

Kardex offers integrated fire protection solutions to help prevent and minimize damage caused by fires in warehouses and storage facilities. These solutions are designed to detect fires early, contain them, and protect the stored goods.

Clean, Controlled & Secure Storage

Protecting high value and sensitive goods is crucial for the electronics industry, find out how automation ensures storage and handling of goods in controlled environments.