Kardex Modernizes MOSCA's Intralogistics with Smart Automated Storage Solutions

24 June 2024, Company News

MOSCA, a traditional family-owned engineering company, is centralizing and streamlining its operations to support its growth and maintain its position as a leader in strapping technology. The new system from Kardex not only meets MOSCA's current needs but also provides scalable solutions to accommodate future expansion.

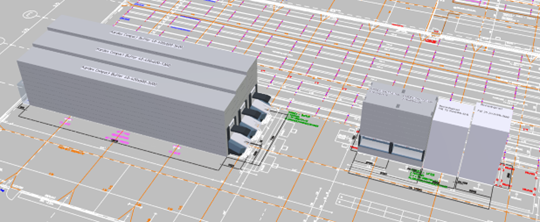

The upgraded system features three Kardex Miniload-in-a-Box, two Kardex Shuttle 500, and the strategic relocation of two existing Megalifts. Additionally, the Kardex Drive interface ensures seamless integration with MOSCA's SAP systems, facilitating enhanced operational efficiency and communication across platforms.

This collaboration marks a significant milestone in modernizing MOSCA's logistics operations by replacing its outdated existing solution with Kardex's advanced automated system.

Key benefits of the new system include:

- Scalability: The configuration of the new system supports potential growth, with capabilities to expand storage space efficiently.

- Cost savings: Reduction in labor costs will be achieved by reducing the number of operators required, thanks to a more efficient system layout.

- Reliability and future-proofing: The modern system addresses the availability issues of spare parts, securing MOSCA's operations against potential downtimes.

- Enhanced safety and ergonomics: The design of the new system minimizes the physical strain on workers, contributing to a safer and more productive working environment.

Oliver Schmidt, System Sales Manager at Kardex, commented: " Our early involvement in the project resulted in a scalable solution that prepares MOSCA for future growth.”

Jürgen Ernst from MOSCA noted: "The collaboration with Kardex allows us to significantly enhance our operations. This modernization prepares us well for our future business needs."

This implementation at MOSCA highlights Kardex's dedication to providing customized, technologically advanced intralogistics systems designed to meet the specific operational demands of the mechanical engineering industry.

About MOSCA

As part of Mosca GmbH, MOSCA Machinery & Equipment GmbH & Co. KG is a family business that has been at the forefront of strapping technology for over 50 years. The company specializes in high quality strapping machines and materials for the secure packaging of goods for transport and storage. With approximately 1,350 employees worldwide, MOSCA has grown into a global company with subsidiaries and distributors in more than 65 countries, offering a comprehensive range of products and services for various industries and applications.

Its philosophy is based on innovation, sustainability and customer focus. Investing heavily in R&D, MOSCA develops advanced products such as the SoniXs ultrasonic sealing system, the Standard-6 belt path and the EVOLUTION range, setting industry standards for quality, performance and cost-effectiveness.

Committed to sustainability, MOSCA practices lean management to minimize waste and uses environmentally friendly materials and processes. The company is also committed to social responsibility through charitable and educational initiatives.

MOSCA is committed to providing comprehensive service and support throughout the product lifecycle, from project analysis to maintenance. Their team provides expert advice, training and technical support to ensure customer satisfaction. With several manufacturing facilities in Germany, Mosca continues to drive technological advancements and strengthen its global market position. The company is headquartered in Waldbrunn, Germany.

About Kardex

Kardex is a leading intralogistics solution provider of automated storage and material handling systems. With two entrepreneurially managed divisions, Kardex Remstar and Kardex Mlog, the Kardex mission is to provide solutions and services to increase the efficiency in storing and handling of goods and materials on a global scale.

The two divisions serve as partners over the entire life cycle of a customer's product or solution. From project analysis to realization and service, Kardex helps improve a customer’s performance every step of the way. With two own production plants in Germany and one in North America, Kardex ensures high-quality solutions. To maintain and strengthen its competitive position within technological innovation and outstanding customer loyalty, Kardex is investing in research and development, its supply chain, the expansion of its service organization as well as in new technology via acquisitions. Kardex actively partners with global leaders who share the same values and complement the Kardex solutions, including AutoStore and Sumobox.

Kardex employs 2,100 team members across 30 countries and has installed over 140,000.

Kontakt

Please fill out our contact form and our experts will help you to find the best solution tailored to your needs.