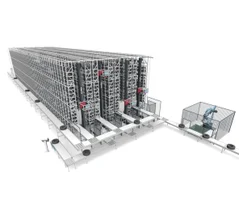

Buffering and Sequencing Solutions for the production area

The production environment places intense demands on processes and material flows. The use of a fully automated buffer has numerous advantages.

It not only absorbs small fluctuations in the production process preventing expensive downtime, but it also ensures that intermediate stored products are returned just-in-time to the production process flawlessly, reliably, and sequentially. All of this takes place around the clock - it’s a 24/7 operation.

The fully automated production buffers from Kardex are characterized by:

- High efficiency

- Easy integration

- Modular expandability

- Minimum investment

Kardex’s standardized storage systems quickly integrate into existing production environments, usually without any structural changes. They fully integrate into production processes - either as a buffer storage between production and shipping or for storing semi-finished products during assembly.

Benefits at a glance

- 100% transparency provides a clear overview of all stored goods

- Sequential delivery to the individual production processes

- Pre-sorted provisions in the correct order

- Access restrictions - protects intermediate storage

- Storage in controlled environments: clean room, cooling, fire protection, etc.

- Automatic connection via conveyor technology and AGV