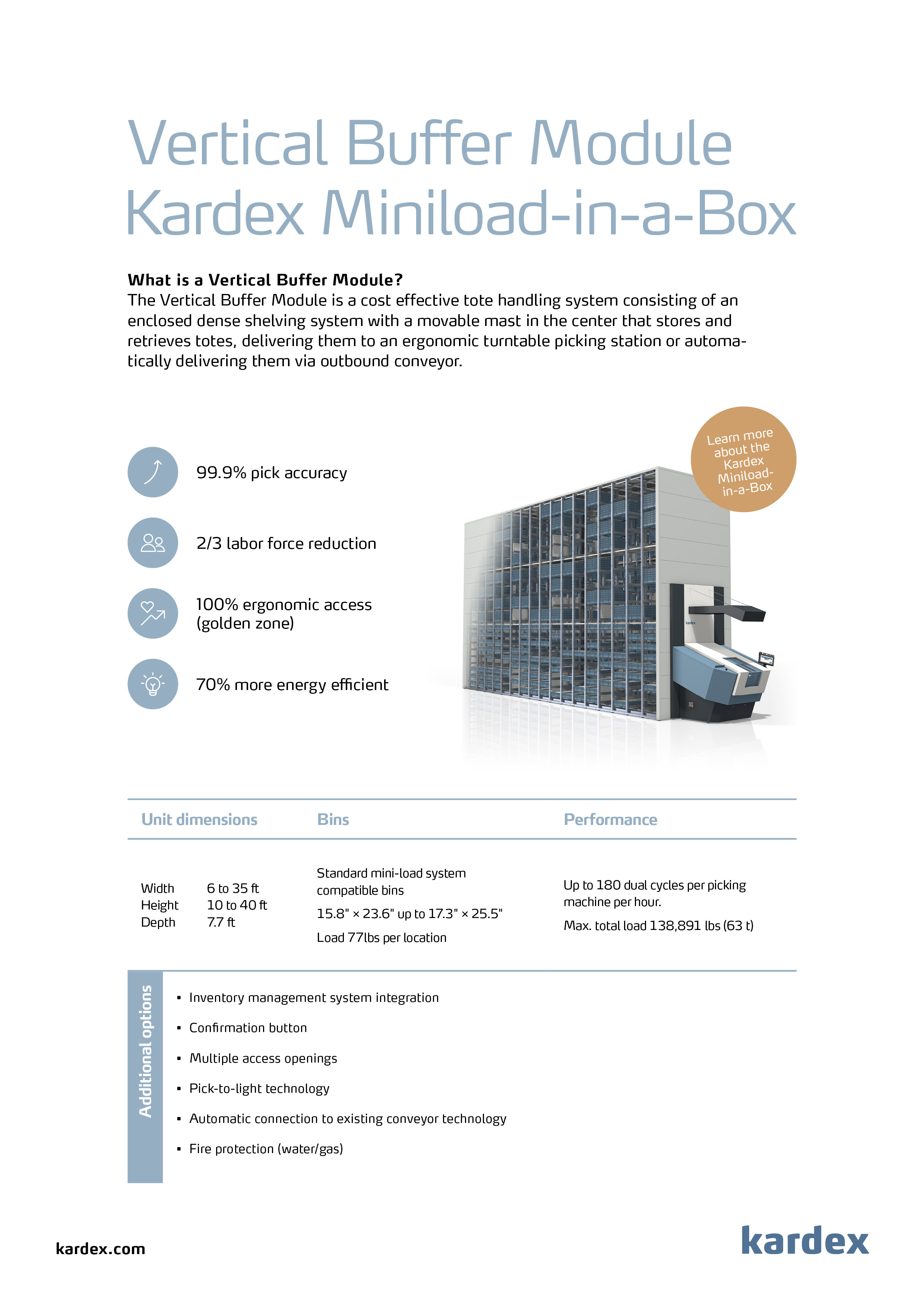

Vertical Buffer Module (VBM)

The Kardex Miniload-in-a-Box is a Vertical Buffer Module (VBM) that provides an efficient solution for fast-growing product ranges with limited storage space.

This scalable bin solution works as a mini-load system and flexibly stores, picks and buffers small parts. With the recently launched version, capable of extending up to 20 meters, the Kardex Miniload-in-a-Box provides valuable benefits. It allows companies to maximize space by utilizing the storage area at a minimal cost.

How does the Vertical Buffer Module work?

Pick small parts quickly and efficiently with the Kardex Miniload-in-a-Box (formerly Kardex Compact Buffer)

To optimize order picking performance for small parts and lightweight goods, the Kardex Miniload-in-a-Box (formerly Kardex Compact Buffer) is the ideal solution. Whether being used to supply a production line with a wide range of products; as buffer storage in the assembly area; or for picking slow-moving parts in the distribution warehouse, the Kardex Miniload-in-a-Box (formerly Kardex Compact Buffer) significantly improves productivity, while guaranteeing accuracy and energy efficiency.

It is flexible and scalable. A work station can consist of one or more units. Companies benefit from optimal storage capacity and performance. They choose from several access opening types and can customize the unit dimensions up to 20 meters long and 12 meters high. This flexibility makes the Kardex Miniload-in-a-Box (formerly Kardex Compact Buffer) an ideal solution for multiple applications. It easily integrates into existing processes and connects to different customer host-systems.

The importance of ergonomic picking is growing. Customers working with the Kardex Miniload-in-a-Box (formerly Kardex Compact Buffer) benefit from ergonomic work stations, which simplify the picking process and improve overall working conditions. At each access opening, items tilt at a 20-degree angle while the goods-to-person principle delivers items directly to the operator, eliminating walk and search time.

Warehouse requirements

- Precise, simple, and fast order picking

- Ergonomic working conditions

- Flexible storage possibilities

- Simple integration

- Modular and scalable

- Controlled access

Benefits at a glance

- Fast order picking and energy efficient

- Pick-to-light technology ensures accurate picking

- Modular and scalable design enables easy integration to existing processes and building dimensions

- Minimal cost for maximum storage capacity

- Quick access to a wide range of items

Components to create the perfect solution

Offering complete flexibility, the Kardex Miniload-in-a-Box (formerly Kardex Compact Buffer) optimally adapts to existing equipment and allows various access openings and picking stations. Up to four access openings can be fitted to the end face, right side, or left side of each unit.

Tab Navigation

Picking station

The turntable is the picking station’s key element. Tilted at a 20-degree angle, it is extremely ergonomic and easy to operate.

While the operator picks the order, the next bin or tray is prepared in the background and placed on the turntable’s rear shelf. As soon as the operator finishes picking one order, the turntable rotates 180-degree and the next bin is ready for picking.

Controlled single access opening

An administrator can control individual access to bins when needed. This is especially important when storing valuable tools and equipment.

Clearance control

The clearance control serves to protect sensitive and valuable items and reduce the risk of crash situations. Vertical light barriers monitor bin heights or overhanging goods in the aisle area.

In the event of an error, either the machinery does not start moving or its movement is interrupted and signals an error message.

Conveyor connection

The Kardex Miniload-in-a-Box (formerly Kardex Compact Buffer) easily connects to existing conveyor technology, either for manual storage and retrieval of bins and trays or for automatic operation and transfer to existing material flow.

The connection fits the end face, right, or left side. It is designed to constantly move bins to fill orders automatically and increase order picking performance. Also, replenishment can be done automatically.

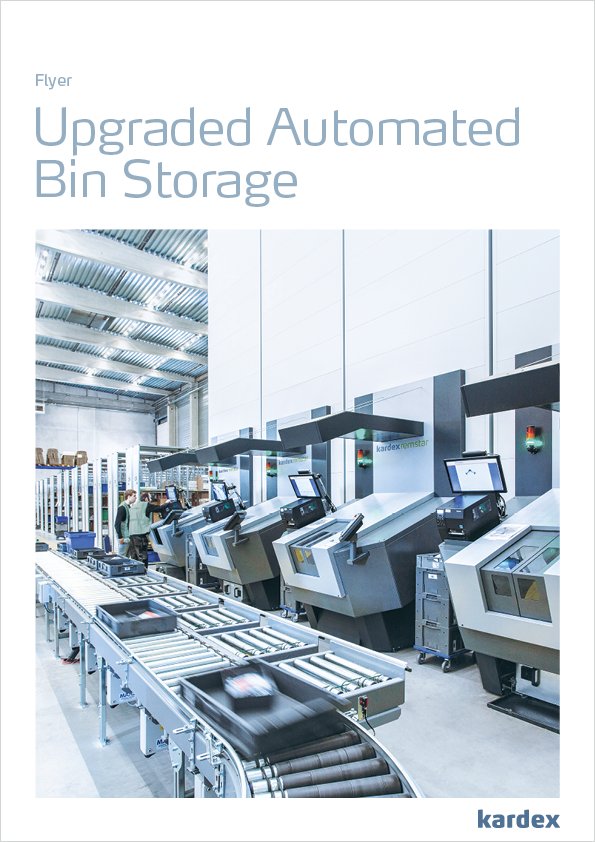

Upgraded automated bin storage

Optimize your intralogistics processes with the new solution for automated bin storage. This accurate bin picking and buffer system will significantly improve order fulfillment processes and save space.

Options for individual requirements

The greatest flexibility for every need

The Vertical Buffer Module is extremely flexible and offers a broad range of optional features. The modular design can be configured for a a diverse range of needs and integrates additional components at any stage, both before or after installation.

The LED pointer identifies the storage and retrieval positions at each picking station. It is a fixed, high-power LED light source that uses a controllable mirror to generate a spot of light projected directly into the compartment of a bin/tray. Without the need for a preset calibration, the light pinpoints the exact location for picking/putting.

The indicator located on the control panel display helps the operator identify storage locations in the bin/tray. This eliminates the need for a time-consuming search. The position indicator quickly and accurately guides the operator to the correct pick/put.

Located externally, LED lighting forms a canopy shape above the access openings to enhance visibility. This is especially helpful when warehouse lighting conditions are poor. The light can be switched on and off via the user display.

Based on individual fire protection requirements, it is possible to install gas nozzle pipes or sprinkler pipes for gas or water extinguishing systems in the area of the field reinforcements.

An externally located socket and various interfaces (2x USB, 1x Ethernet) are available for the picking station.

Innovative unit software with a capacitive touchscreen

For optimal performance in the warehouse

The software for the Vertical Buffer Module meets the highest standards: it offers a modern operating concept with a newly developed, capacitive touchscreen for even faster and more intuitive operation. The associated software is web-based and therefore works with a wide range of hardware.

Main operating features:

- Modern and intuitive

- Capacitive touchscreen

- Virtual keyboard

- Optional connection to external keyboards or barcode scanners (USB)

- Operating with new browsers is possible

- Multilingual operations

Technical data

| Performance | High order picking performance based on bin cycles and number of order lines. Max. total load 63 metric tons |

|---|---|

| Bins | Standard mini-load system compatible bins 600 x 400 mm (24.6 x 16.3 in) Load 35 kg (77.2 lbs) | bin, Individually designed Kardex VBM Boxes (640 x 440 x 140 mm/25.2 x 17.3 x 5.5 in) are available |

| Width | 1,920 to 19,970 mm (75.6 to 786.22 in) |

| Depth | 2,350 mm (92.5 in) |

| Height | 3,000 -12,000 mm (118.11 to 472.44 in) in 100mm steps |

| Unit vertical steps | 100 mm (3.9 in) increments |

Additional options

An innovative storage box - flexible and robust to fit warehouse needs

The Kardex VBM Box is a storage and transport box that includes a divider system. With dimensions 640 x 440 x 140 mm (25.2 x 17.3 x 5.5 in), the box is perfect for the Vertical Buffer Module Kardex Miniload-in-a-Box (formerly Kardex Compact Buffer). Storage boxes can be divided or adapted at any time using transverse and longitudinal dividers for increased flexibility. The height extends in a 50 mm (1.9 in) grid using push-on frames.

Controlled environment

Parts, raw materials and products often require special storage conditions. Depending on your individual needs, we supply four optional controlled environment solutions. These solutions can be integrated into your storage and retrieval system and, as a result, your sensitive goods are always protected.

.jpeg)