Automated Storage without a Load Carrier

In many storage applications, using load carriers like pallets and trays isn’t possible due to item size, material, or process constraints. Kardex solutions offer carrier-free storage that maximizes efficiency and adapts to your unique storage needs.

With Kardex Mlog's automated, carrier-free storage solutions, you can streamline order picking and achieve higher dynamics. Our carrier-free systems also maximize space usage offering compact storage.

Features & Benefits

-

Improved Efficiency

Our automated storage system eliminates the need for manual handling of load carriers, reducing labor costs and increasing productivity

-

Space Saving

By storing items directly in our automated system, you can optimize your warehouse space by up to 66%, allowing for more inventory stored in the same area

-

Improved Accuracy

With automated storage without a load carrier, errors caused by manual handling of load carriers are eliminated, ensuring that items are accurately stored and retrieved

-

Reduced Labor Costs

By automating tasks such as storage and retrieval, you can reallocate labor resources to higher-value activities or reduce overall staffing needs

-

Enhanced Inventory Management

Our automated system provides real-time inventory tracking and monitoring, enabling better decision-making and improved supply chain management

-

Increased Uptime and Reduced Downtime

Our automated storage system minimizes the risk of errors caused by human error, reducing downtime and increasing overall system uptime

Improved Efficiency

Our automated storage system eliminates the need for manual handling of load carriers, reducing labor costs and increasing productivity

Space Saving

By storing items directly in our automated system, you can optimize your warehouse space by up to 66%, allowing for more inventory stored in the same area

Improved Accuracy

With automated storage without a load carrier, errors caused by manual handling of load carriers are eliminated, ensuring that items are accurately stored and retrieved

Reduced Labor Costs

By automating tasks such as storage and retrieval, you can reallocate labor resources to higher-value activities or reduce overall staffing needs

Enhanced Inventory Management

Our automated system provides real-time inventory tracking and monitoring, enabling better decision-making and improved supply chain management

Increased Uptime and Reduced Downtime

Our automated storage system minimizes the risk of errors caused by human error, reducing downtime and increasing overall system uptime

Insights & Customer Success Stories

Partner with an Industry Leading Provider

At Kardex, we understand the importance of efficient and accurate storage solutions that cater to industries such as manufacturing, logistics, and e-commerce. Our automated storage systems are designed to optimize space utilization, reduce labor costs, and improve inventory management.

ASRS wtihout a load carrier: Kardex's automated storage without load carrier eliminates the need for load carriers, ensuring accurate and efficient storage and retrieval processes. This feature is particularly beneficial in high-volume warehouses where manual handling can lead to errors and inefficiencies.

Real-time Inventory Management: Our automated storage systems provide real-time inventory management capabilities, enabling businesses to track their stock levels accurately and make informed decisions about production and supply chain planning.

Reduced Labor Costs: By automating the storage and retrieval process, our solutions reduce labor costs associated with manual handling and improve productivity. This feature is particularly beneficial in industries where labor costs are high or where there is a shortage of skilled workers.

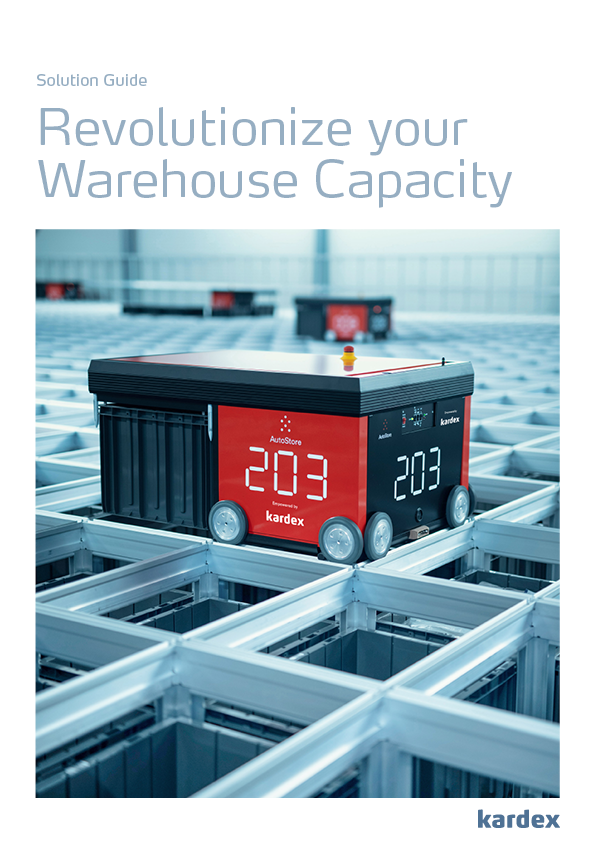

Increased Efficiency: Our automated storage systems optimize space utilization by storing items in compact configurations, reducing travel time for robots and improving overall warehouse efficiency.

Improved Accuracy: By eliminating the need for load carriers, our solutions reduce errors caused by manual handling and improve inventory accuracy. This feature is particularly beneficial in industries where product quality or safety are critical concerns.

Kardex's automated storage systems, which do not require a load carrier, provide numerous advantages that assist businesses in enhancing their warehouse operations, cutting costs, and boosting productivity.

More Solutions from Kardex

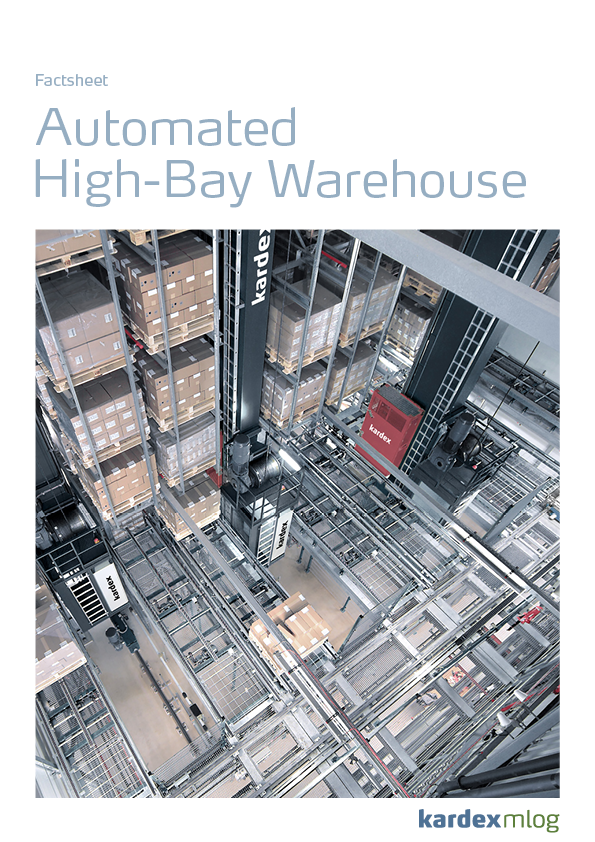

High-Bay Warehouses

Looking for the optimal storage solution for large, palletized goods while using minimal warehouse footprint? Kardex Mlog high-bay warehouses with a height up to 45 meters and providing single- or multi-deep storage offer maximum flexibility and optimal use of available space. With automated processes from inbound to outbound, you can streamline operations and boost efficiency.

Miniload System

The miniload system is a tailor-made solution with a height of up to 24 meters. It offers the possibility of single- or multi-deep storage and manages various load-handling devices.