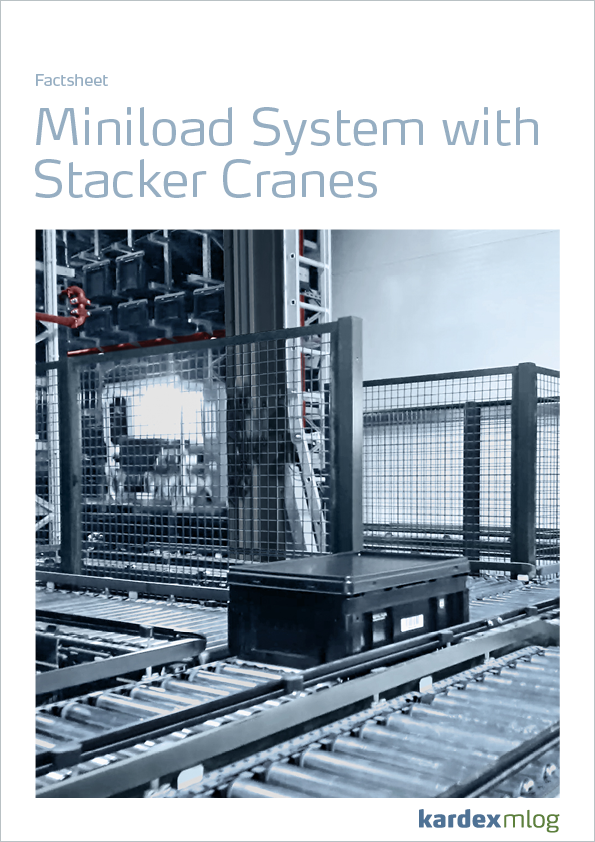

Miniload System

Maximize storage efficiency and reduce costs with our Miniload Systems — automated solutions designed for rapid access and high-performance storage in a compact footprint.

A miniload system is an automated storage and retrieval system (ASRS) designed for efficient handling and organization of small unit loads. Our Miniload Systems are suitable for a wide range of applications, storing items in bins, cartons, or on trays. Stacker cranes manage all the storage and retrieval operations. Combining high-density storage with the ability to use full room height, these Miniload Systems provide excellent throughput and flexibility. With a height of up to 24 meters, they feature a variety of load-handling devices and provide single or multiple-deep storage.

Features & Benefits

-

Great Flexibility

Enjoy maximum flexibility with individualized solutions

-

High Density Storage

Store a large number of items in a compact space

-

Automated Retrieval

Benefit from fast and accurate picking and put-away operations

-

Increased Performance

Increase process speed and reliability

-

Transparent Inventory Management

Leverage real-time inventory tracking and monitoring

-

Reduced Labour Costs

Reduce labor costs associated with manual picking and put-away

Great Flexibility

Enjoy maximum flexibility with individualized solutions

High Density Storage

Store a large number of items in a compact space

Automated Retrieval

Benefit from fast and accurate picking and put-away operations

Increased Performance

Increase process speed and reliability

Transparent Inventory Management

Leverage real-time inventory tracking and monitoring

Reduced Labour Costs

Reduce labor costs associated with manual picking and put-away

Insights and Customer Success Stories

High-Density Warehouse Automation

Our Miniload Systems are automated storage and retrieval (AS/RS) solutions developed by Kardex Mlog to optimize warehouse operations. This well-established technology uses stacker cranes to store and retrieve items from multiple levels of shelving, maximizing available space while minimizing labor costs.

One of the key features of our Miniload Systems is the flexibility to configure them individually to meet your specific needs. Building a miniload system can significantly reduce lead time compared to manual storage, resulting in saving space as well as guaranteeing high capacity and throughput.

Our Miniload Systems offer numerous benefits to warehouse operations. For instance, it eliminates the need for manual handling errors, reducing labor costs and increasing picking accuracy. Additionally, the automated retrieval process reduces lead times for picking and shipping orders.

In real-world applications, our Miniload Systems have been shown to have a significant impact on warehouse operations. Automating manual storage areas, improving picking processes, and freeing up space for further growth.

Overall, our Miniload Systems are well-established solutions that can help warehouses streamline operations, reduce labor costs, and increase efficiency.

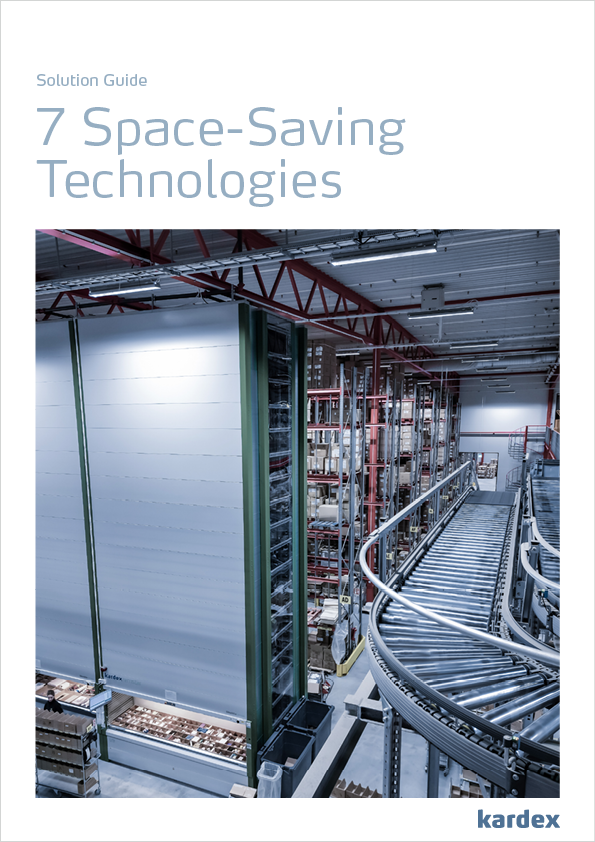

More Solutions from Kardex

Conveyor Systems

Kardex develops reliable, high-performance solutions based on many years of experience with a wide range of standardized conveyor systems and complex material flow systems.

Stacker Cranes for Pallets and Miniloads

Kardex Mlog's stacker cranes ensure efficient automated storage and retrieval of pallets and bins. Their high, compact design maximizes space usage in high-bay warehouses, delivering high performance and reliability for optimized warehouse logistics.

Optimize Your Bin Storage Efficiency

Gain essential insight into selecting the best storage system for your bin-stored small parts.