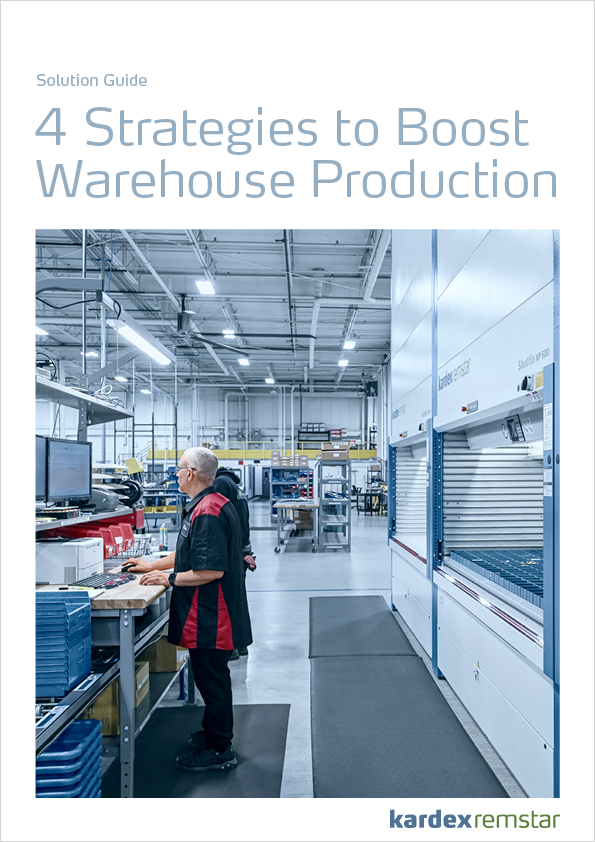

Automated Solutions for Mechanical Engineering

Discover how Kardex' automated solutions transform your operations. Learn how to enhance efficiency, save costs, and streamline material flow.

In the mechanical engineering industry, efficiency, flexibility and productivity are essential. Constantly changing market conditions and an ever-growing range of tools and components often challenge logistics managers.

Kardex provides scalable and flexible intralogistics solutions that ensure smooth material flow and accurate inventory management, optimizing overall supply chain efficiency. Our automated systems offer significant cost savings, reliable and low-maintenance operations, and enhanced safety features. Customizable to your needs, Kardex solutions are easy to operate and provide actionable analytics for streamlined operations and improved decision-making.

Features & Benefits

-

Efficiency & Productivity

Increase throughput with optimized material handling processes

-

Ergonomics

Protect your workforce with advanced safety features

-

High Density Storage

Save space with compressed storage for tools and components in different sizes

-

Cost Savings

Reduce labor and operational costs through automation

-

Scalability & Flexibility

Adapt to changing demands with scalable solutions

-

Actionable Analytics

Make informed decisions with real-time data and analytics

Efficiency & Productivity

Increase throughput with optimized material handling processes

Ergonomics

Protect your workforce with advanced safety features

High Density Storage

Save space with compressed storage for tools and components in different sizes

Cost Savings

Reduce labor and operational costs through automation

Scalability & Flexibility

Adapt to changing demands with scalable solutions

Actionable Analytics

Make informed decisions with real-time data and analytics

Customer Success Stories

Maximizing Available Space

Custom-Built Solutions to Fit Your Needs

In the mechanical engineering industry, efficiency, flexibility, and productivity are essential. Kardex' automated intralogistics solutions are designed to meet these demands, providing custom-built solutions that address specific industry challenges and enhance your operations. For instance, companies using Kardex solutions have reported up to 92% floor space recovery.

By leveraging our advanced technologies, you can achieve significant improvements in your supply chain and assembly processes.

- Improved Material Flow and Productivity

Kardex products like the Kardex Shuttle or the Kardex Miniload-in-a-Box automate the picking process, significantly speeding up assembly line operations and increasing overall productivity. - Ergonomics

Enhance your mechanical engineering operations with Kardex' ergonomic intralogistics solutions. All our storage systems deliver the goods directly to the operator at ergonomic heights, eliminating the need to search for the needed item or climb ladders. Our automated lifting devices prevent heavy lifting, while safety features minimize injury risks. Optimize your workplace with Kardex for a healthier, more productive team. - High Density Storage

The Kardex Shuttle, for example, offers vertical storage capabilities, maximizing your storage space and reducing the footprint needed for inventory storage by up to 85%. Storing items at the available floor-to-ceiling height allows production facilities often to expand their operations without the need for physical expansions or relocations. - Cost savings

Reduce labor costs and operational expenses with our advanced automated storage and retrieval systems. Enjoy significant savings by minimizing errors and downtime, while enhancing productivity and inventory management. Invest in Kardex for a cost-effective and streamlined operation. - Scalability & Flexibility

Easily adapt to changing business needs, such as growth or a more diverse product portfolio, with our advanced intralogistics systems. The Kardex Shuttle, for example, is an ideal solution for a changing product portfolio. It stores goods weighing up to 1000 kg and provides maximum storage capacity in a minimum footprint. - Actionable Data and Analytics

Utilize real-time data and analytics to make informed decisions. Kardex systems come equipped with software that provides comprehensive insights into inventory levels, usage patterns, and system performance, helping you optimize your operations and plan effectively.

More Solutions from Kardex

Buffer Storage Eliminates Downtime

Efficient Order Picking

Find a solution that optimizes order picking performance and space while guaranteeing high precision for storing, managing, and picking single items.