Automated Solutions for Food & Beverage

Kardex automated storage and retrieval systems (ASRS) provide the food and beverage industry with solutions that efficiently manage various product sizes while ensuring optimal environmental control and meeting the high demands of speed, accuracy, and flexibility in both sectors.

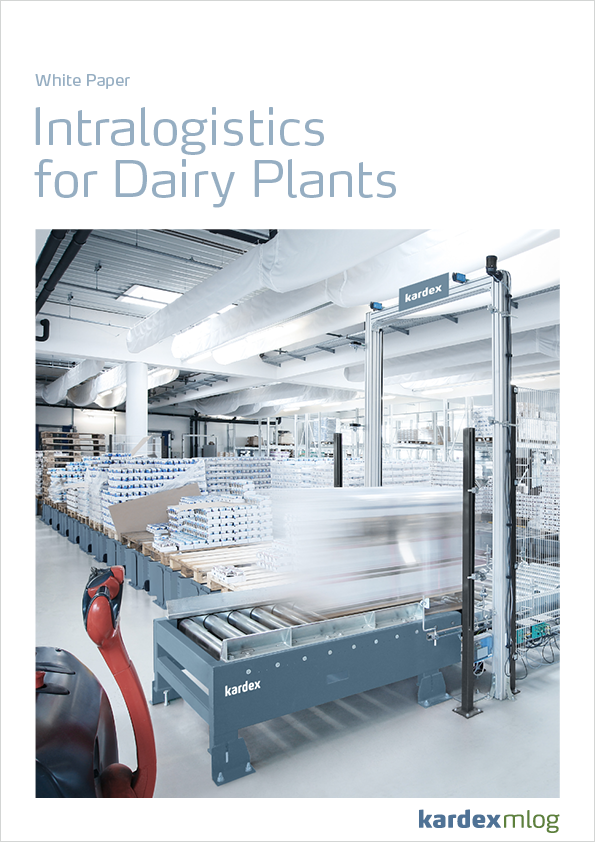

In a food storage facility, maintaining a hygienic environment and ensuring seamless cold chain management is essential. Tracking Best Before Dates (BBD) and batches, along with handling various product sizes, poses significant challenges with manual processes. Kardex automated solutions streamline these operations, ensuring reliable batch tracking, cold chain integrity, and hygienic storage, while overcoming the complexities of manual picking and staging.

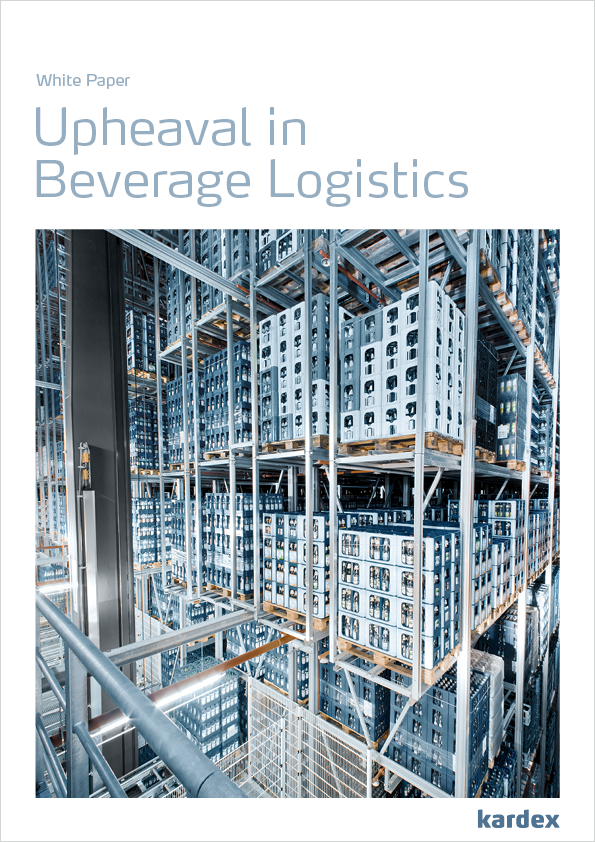

In a beverage distribution center, moving heavy, bulk product loads efficiently and quickly is critical, especially during seasonal demand peaks. Our solutions ensure high throughput and fast transport times, adapting swiftly to changing capacity needs.

Features & Benefits

-

Temperature & Hygiene Control

Maintain food safety with hygienic, temperature-controlled solutions that meet strict industry regulations

-

Batch Traceability

Ensure seamless batch and BBD tracking with integrated software for real-time food safety compliance

-

Space Optimization

Maximize storage efficiency with scalable, modular solutions that adapt to different product sizes

-

Heavy Load Handling

Efficiently store and transport heavy beverage loads with high throughput and minimal manual effort

-

Peak Demand Management

Automate buffer storage, ensuring timely availability of materials (e.g. packaging for peak production)

-

Tailored Solutions

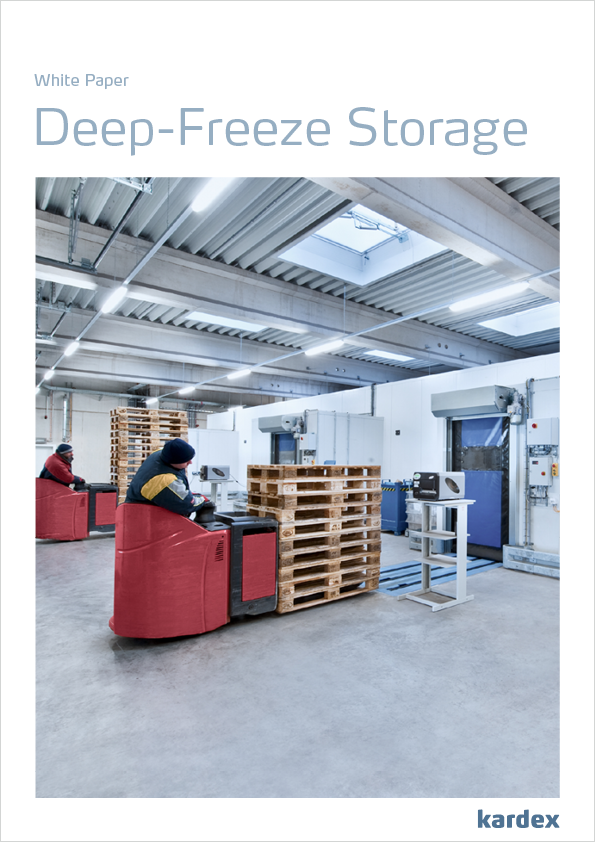

Customize your ASRS with deep-freeze, custom temperature zones, or virtual tracking of maturation zones

Temperature & Hygiene Control

Maintain food safety with hygienic, temperature-controlled solutions that meet strict industry regulations

Batch Traceability

Ensure seamless batch and BBD tracking with integrated software for real-time food safety compliance

Space Optimization

Maximize storage efficiency with scalable, modular solutions that adapt to different product sizes

Heavy Load Handling

Efficiently store and transport heavy beverage loads with high throughput and minimal manual effort

Peak Demand Management

Automate buffer storage, ensuring timely availability of materials (e.g. packaging for peak production)

Tailored Solutions

Customize your ASRS with deep-freeze, custom temperature zones, or virtual tracking of maturation zones

Customer Success Stories

Food & Beverage ASRS in action

Custom-Built Solutions to Fit Your Needs

At Kardex, we provide ASRS solutions specifically designed to meet the unique challenges of the food and beverage industries. Explore the wide range of benefits that can enhance your warehouse operations.

Temperature-Controlled Storage

We offer a wide range of temperature-controlled storage solutions that maintain constant temperatures between -30 degrees to +55 degrees Celsius with precise control of +/-1 K. This ensures optimal conditions, even for deep-freeze environments, while managing humidity levels effectively. Our solutions support warehouses requiring different temperature zones, crucial for storing frozen products and other food items like meat, confectionery, or dairy products.

Efficient BBD & Batch Management

Our software solutions ensure 100% seamless and reliable traceability of individual production batches, a critical requirement in the food and beverage industry.

Storing Heavy-Weight Loads

In the beverage industry, where heavy product loads must be stored, transported, and made available in a timely manner, Kardex automated storage solutions excel. Our solutions efficiently handle heavy-weight loads and quantities, even during peak demand periods.

Flexible Use of Storage Space

The food industry deals with a wide variety of products, including finished goods, semi-finished goods, packaging, and auxiliary materials. Kardex solutions maximize storage space utilization and enable fast and reliable order picking, thus ensuring efficient goods management.

Optimal Production Flow

Our ASRS solutions can act as buffer storage, optimizing the use of production space. They store a wide variety of products and raw materials, ensuring fast and automatic just-in-time access when needed for production.

More Solutions from Kardex

High-Bay Warehouse

Are you looking for the optimal storage solution for large, palletized goods with minimal floor space? With heights of up to 45 meters and single or multi-deep storage, Kardex Mlog high-bay warehouses offer maximum flexibility and optimal use of available space. With automated processes from inbound to outbound, you can streamline operations and increase efficiency.