Solutions for the Electronics Industry

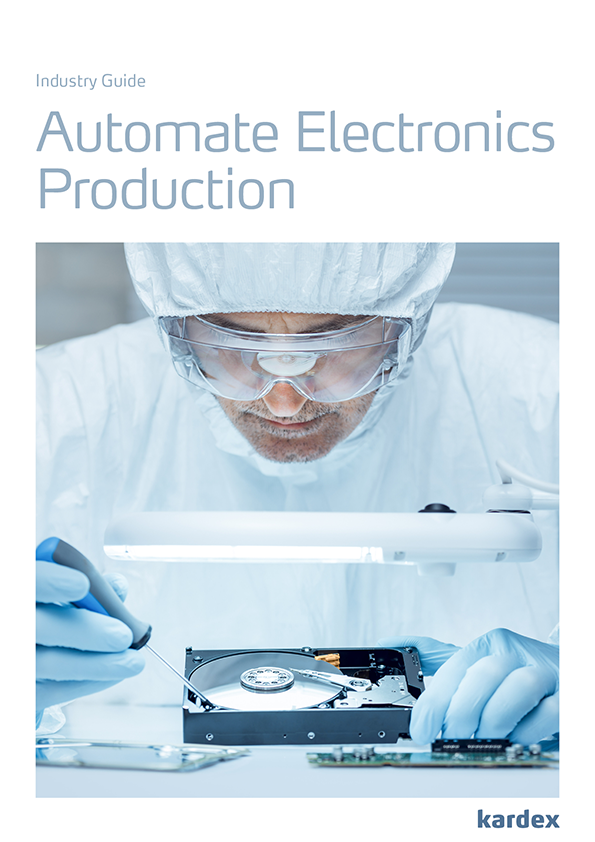

Comprehensive ESD protection and storage under controlled temperatures or with relative humidity are just a few of the options Kardex offers its customers in the electronics industry.

Efficient intralogistics is critical to remaining competitive in the industry. With increasing demands for rapid production and accurate inventory control, automated storage and retrieval systems provide compact, dust-free storage of electronic components. They streamline operations, prevent material obsolescence, and ensure fast access to components and full traceability of parts and materials.

Kardex intralogistics solutions help electronics manufacturers automate storage and order picking, minimize errors, improve space utilization, and protect sensitive materials. These solutions ensure controlled conditions for components, which is critical for maintaining product integrity and supporting seamless production.

Features & Benefits

-

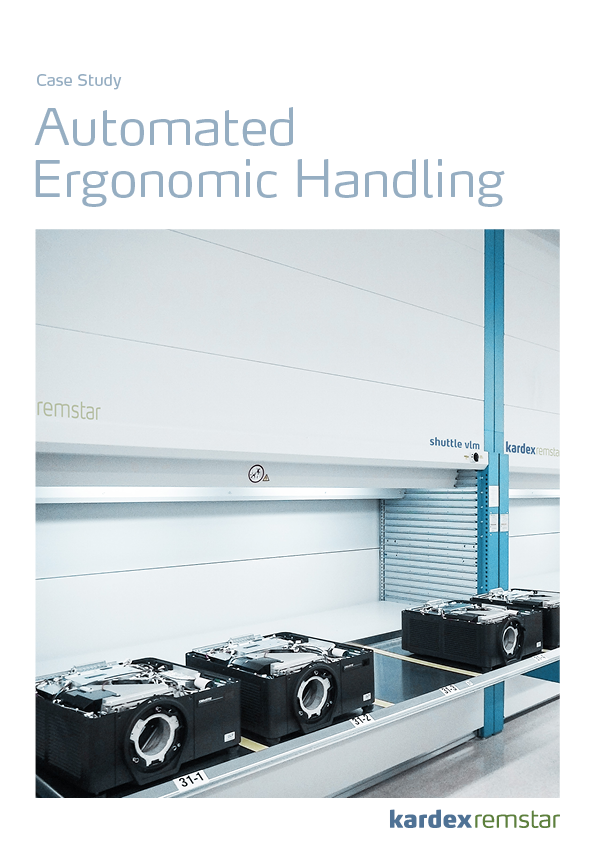

Space Saving

Highly dense storage reduces footprint size by up to 85%

-

Accurate Inventory

Real-time monitoring of stock levels through the Enterprise Resource Planning (ERP) system

-

Climate Controlled

Option to regulate the humidity and temperature when storing sensitive items

-

Dust-Free Storage

The necessary requirements for cleanroom conditions are met

-

Efficient SMD Handling

Flexibility to constantly adapt to SMD reels in various dimensions

-

ESD Protection

Optional, comprehensive ESD-protection available

Space Saving

Highly dense storage reduces footprint size by up to 85%

Accurate Inventory

Real-time monitoring of stock levels through the Enterprise Resource Planning (ERP) system

Climate Controlled

Option to regulate the humidity and temperature when storing sensitive items

Dust-Free Storage

The necessary requirements for cleanroom conditions are met

Efficient SMD Handling

Flexibility to constantly adapt to SMD reels in various dimensions

ESD Protection

Optional, comprehensive ESD-protection available

Insights & Customer Success Stories

Optimizing electronics warehouse operations

Custom-Built Solutions to Fit Your Needs

In the electronics industry, precision, speed, and flexibility are essential to staying ahead. As product life cycles shorten and customer demands grow, managing your supply chain efficiently becomes increasingly complex. Kardex offers automated solutions designed specifically to meet the unique challenges you face.

Tailored Solutions for High-Precision Operations

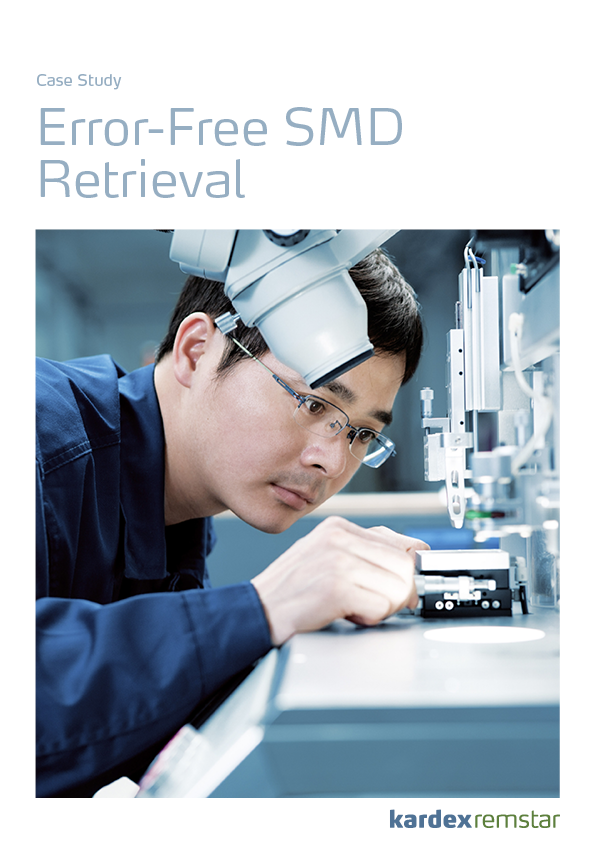

From managing sensitive electronic components to streamlining the assembly process, Kardex solutions are designed to meet the high demands of your industry. Our systems provide fast, accurate access to materials while maintaining optimal conditions for sensitive items, reducing the risk of errors and delays. The use of advanced software prevents material aging and reduces the risk of partially used SMD reels, for example. It ensures accurate inventory control and traceable material flow.

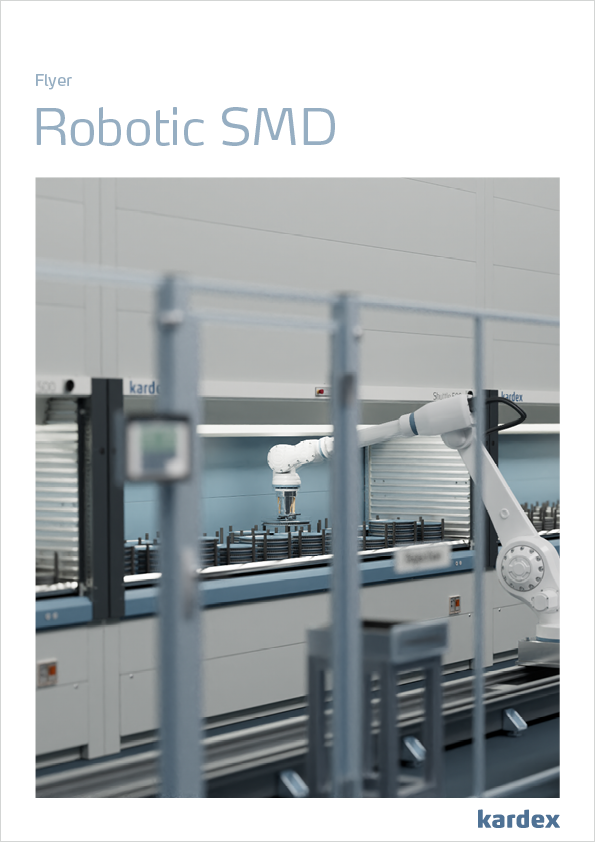

Innovative Robotic SMD Handling

Our solution portfolio is state of the art. We embrace trends and market needs so that our customers can benefit from new solutions and opportunities. With our Robotic SMD Handling, you get a fully automated solution for picking and storing SMD reels and trays with the highest accuracy, eliminating errors that can cause delays and waste in production. The electronics industry benefits from 24/7 uninterrupted operation of the system, which significantly increases overall productivity.

Your Just-in-Time Production

The electronics industry requires seamless synchronization between production and logistics. With Kardex, you gain the ability to keep pace with just-in-time production schedules, ensuring you have the right materials at the right time, every time. Our automated storage and retrieval systems (ASRS) are designed to integrate seamlessly into your workflow, boosting productivity and minimizing downtime.

Protecting Your High-Value Inventory

We know how critical it is to safeguard expensive, high-tech components. Kardex solutions offer secure, climate-controlled storage for your valuable inventory, ensuring your materials are protected from environmental risks like humidity, temperature fluctuations, and dust. This reduces waste and enhances the quality of your final products.

Scaling with Your Business Growth

As your business grows, you need solutions that can scale with you. Kardex's modular systems allow for easy expansion, enabling you to adapt quickly to changing demands without significant disruption. Whether you're ramping up production or diversifying your product lines, our solutions grow alongside your operations.

End-to-End Support and Integration

At Kardex, we don’t just provide products—we offer complete solutions. Our team works with you from initial consultation through system design, implementation, and ongoing support. We ensure our systems integrate seamlessly with your existing processes, providing continuous support to optimize your operations and maintain peak performance.

More Solutions from Kardex

Clean Room Solutions

At Kardex, we know how important it is to maintain precise storage conditions. Our clean room solutions ensure contamination-free storage and meet the highest industry standards. Equipped with features like pressure control, optimized airflow, airlocks, and pallet changers, they preserve the integrity of your clean room environment.

Temperature-Controlled Storage

A growing number of goods are temperature-sensitive and require constant storage temperatures. With years of experience working with the pharmaceutical and food and beverage industries, we understand the stringent guidelines companies face and offer temperature-controlled storage to meet these.

Automate Electronics Warehouses for Maximum Efficiency

Discover how automation can transform your electronics warehouse to improve picking accuracy and ensure a controlled environment for sensitive components.