Buffering & Sequencing Solutions

Discover how Kardex automated solutions enable space-saving and efficient buffering and sequencing processes. Improve space utilization, reduce packing and shipping downtime, and increase productivity with our cost-effective systems.

Warehouse and production operations use buffer systems when their processes

include a wait or hold step, their material handling process requires reserve inventory

to manage fluctuating demands, or when they require a quick and accurate order

consolidation before packing or shipping. Kardex offers scalable and flexible solutions that reduce operator search time, save floor space, and ensure that goods are always available at the right time.

Features & Benefits

-

Space-Saving Storage

Save up to 85% of floor space compared to traditional systems

-

Sequenced Delivery

Optimize packaging and/or shipping with sequenced just-in-time bin delivery

-

Just-in-Time Delivery

Take advantage of the just-in-time retrieval of the bins when they are needed

-

Flexible Automation

Easily integrate with conveyor systems, AGVs, or semi-automated processes

-

Cost-Efficient Scalability

Minimize investment with a modular system that grows with your business

-

Transparent Inventory Management

Gain valuable insights with real-time tracking and inventory management

Space-Saving Storage

Save up to 85% of floor space compared to traditional systems

Sequenced Delivery

Optimize packaging and/or shipping with sequenced just-in-time bin delivery

Just-in-Time Delivery

Take advantage of the just-in-time retrieval of the bins when they are needed

Flexible Automation

Easily integrate with conveyor systems, AGVs, or semi-automated processes

Cost-Efficient Scalability

Minimize investment with a modular system that grows with your business

Transparent Inventory Management

Gain valuable insights with real-time tracking and inventory management

Customer Success Stories

Optimized Buffering in Action

Custom Solutions for Buffering and Sequencing

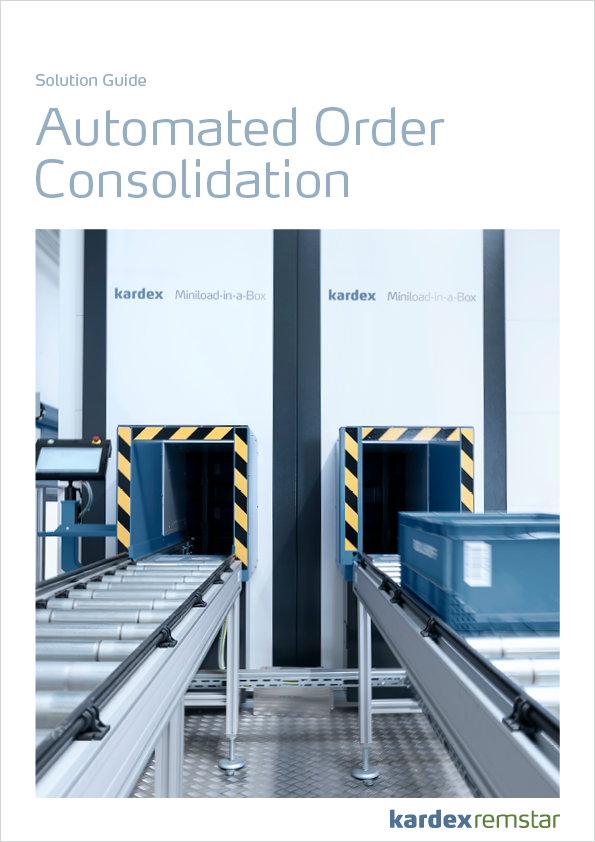

Warehouse operations and production lines each have unique challenges, from managing fluctuating demand to improving material flow. Kardex offers customized buffering and sequencing solutions that adapt to your specific needs and provide unmatched flexibility, scalability, and efficiency. With the Kardex Miniload-in-a-Box, we offer a solution to create a fully or partially automated order consolidation process that helps you to save floor space, speed up processes, and increase accurate, on-time deliveries.

Here’s how Kardex solutions can optimize your workflow:

Just-in-Time Delivery

Our Vertical Buffer Module, the Kardex Miniload-in-a-Box and AutoStore™ system ensure that goods are delivered exactly when needed, supporting continuous material flow and minimizing delays. By automating retrieval, you eliminate idle times and increase throughput. When used for order consolidation, the Kardex Miniload-in-a-Box retrieves all bins related to the same order when the order is complete and ready to ship.

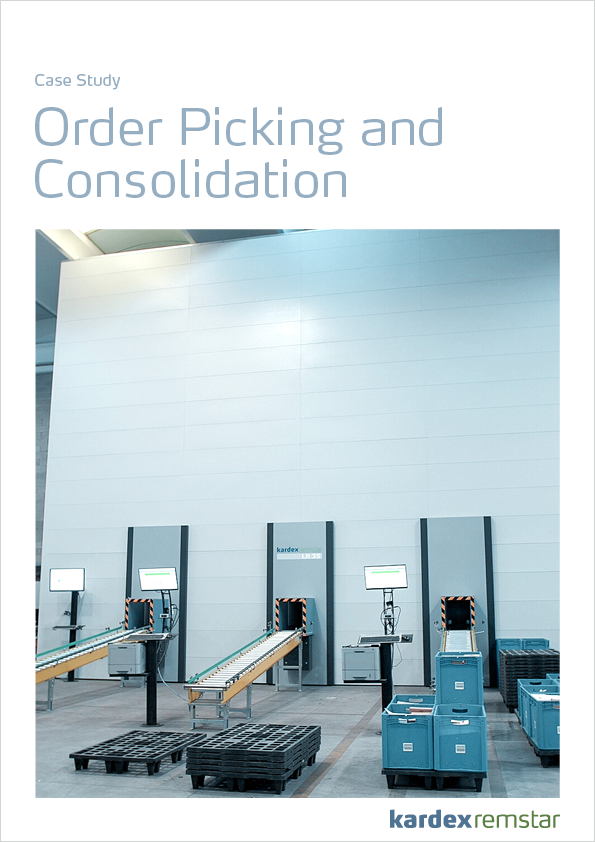

Sequenced Delivery for Packaging & Shipping

Paired with the Kardex JMIF software, the Kardex Miniload-in-a-Box retrieves items in the correct sequence for packaging or shipping. This reduces manual sorting and ensures that packaging is efficient and accurate. Similarly, the AutoStore system, integrated with FulFillX software, streamlines item retrieval and sequencing for high-speed operations, further enhancing packaging accuracy and workflow efficiency.

Flexible Automation

Kardex systems easily integrate with conveyor systems, AGVs, or semi-automated processes, allowing you to choose the level of automation that best suits your needs. Whether you’re automating a small warehouse or a large distribution center, our solutions scale as your business grows.

Space-Saving Storage

Maximize storage capacity and save up to 85% of floor space compared to traditional shelving systems. The Kardex Miniload-in-a-Box and AutoStore system offer high-density vertical storage, ensuring efficient use of your available space.

Cost-Efficient Scalability

The Kardex Miniload-in-a-Box can expand up to 20 meters in length, accommodating growing storage needs. While the AutoStore system offers vertical scalability, reaching heights of up to 6 meters to maximize storage density. Their modular design allows you to add capacity as needed, minimizing upfront investment and keeping operational costs in check.

Real-Time Data & Analytics

Gain complete visibility into your operations with the Kardex Power Pick software and FulFillX with our AutoStore system. It provides real-time tracking and data insights into inventory levels and system performance, enabling data-driven decisions that boost productivity and accuracy.

More Solutions from Kardex

Kardex Miniload-in-Box

The Kardex Miniload-in-a-Box is an efficient solution for fast-growing product ranges with limited space. It flexibly stores, picks, and buffers small parts. It is ideal to automate order consolidation and order picking processes.

Intuitive Picking Assistant

The Intuitive Picking Assistant (IPA) elevates picking processes of AutoStore™ solutions to the next level. By projecting all relevant picking information it guides the operator through the picking process.

Streamline Your Warehouse with Automated Order Consolidation

Discover how Kardex’s automated order consolidation solutions can boost efficiency, reduce space, and improve order accuracy in your operations.