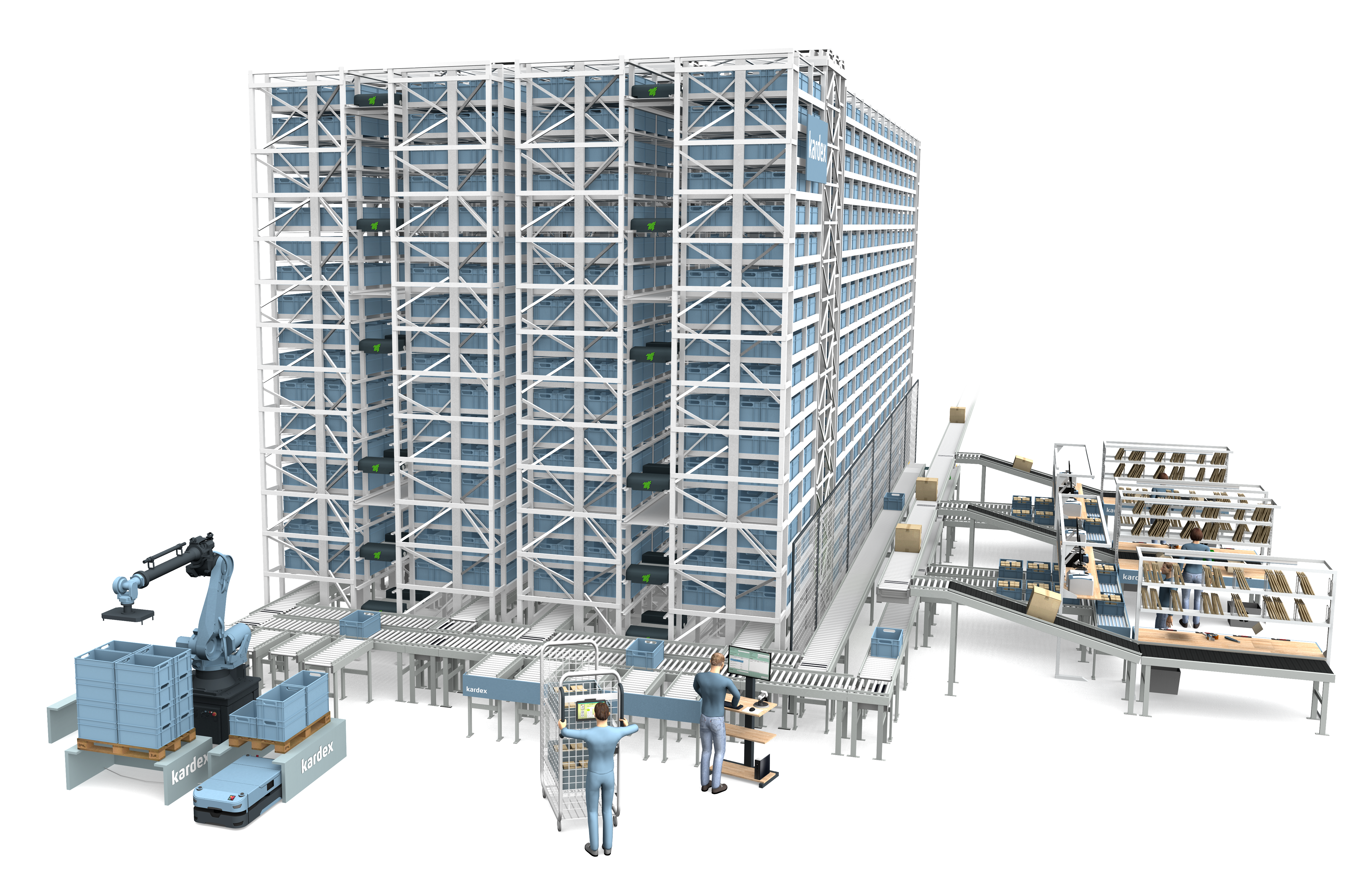

Bin Shuttle System

The innovative bin shuttle system offered by Kardex is an automated small parts warehouse designed to meet current and future needs. It dramatically increases warehouse capacity and performance while reducing costs.

Ideal for industries such as wholesale, retail, e-commerce, the manufacturing industry, and 3PL, this system delivers unmatched efficiency and scalability. Flexibly scalable in terms of dimensions and performance, the bin shuttle system is the perfect solution for automated small parts storage loads of up to 50 kg. The bin shuttle system impresses with maximum storage density, flexible scalability, enormous robustness, and simple integration.

Features & Benefits

-

Maximized Storage Density

Achieves maximum storage capacity within a minimal footprint

-

High System Availability

Ensures continuous operation and process security with reliable performance

-

Energy Efficiency

Reduces energy consumption, lowering operational costs and environmental impact

-

Easy Integration

Seamlessly integrates with existing IT systems and warehouse infrastructure

-

Enhanced Throughput

Supports high throughput for faster order processing and delivery

-

Robust & Durable Design

Engineered for long-lasting performance, even in demanding environments

Maximized Storage Density

Achieves maximum storage capacity within a minimal footprint

High System Availability

Ensures continuous operation and process security with reliable performance

Energy Efficiency

Reduces energy consumption, lowering operational costs and environmental impact

Easy Integration

Seamlessly integrates with existing IT systems and warehouse infrastructure

Enhanced Throughput

Supports high throughput for faster order processing and delivery

Robust & Durable Design

Engineered for long-lasting performance, even in demanding environments

Insights

How Does a Bin Shuttle System Work?

Optimize Industrial Storage with a Bin Shuttle System

The bin shuttle system is a powerful solution tailored for industrial environments, where efficient storage and retrieval of small parts are critical. Engineered to meet the demanding needs of industries such as automotive, electronics, and manufacturing, this system enhances storage density and boosts operational throughput.

Wholesale, retail, and e-commerce

A wide variety of products, rapidly changing ranges, and peak loads are typical challenges in the wholesale, retail, and e-commerce industries. They can all be tackled with a highly efficient bin shuttle system. The high throughput of a bin shuttle system allows returns or special promotions to be prioritized and integrated into the order-picking process. Mixed returns bins eliminate the need for time-consuming, item-specific returns storage and facilitate returns processing.

Manufacturing industry

Efficiency and responsiveness to changing market conditions are key in the manufacturing industry. With short product life cycles, new logistics and manufacturing processes are becoming increasingly important. With the bin shuttle system, you can bring your logistics processes up to date, whether in the automotive, electronics, or mechanical engineering industries. It provides you with a flexible logistics solution to increase productivity and delivery accuracy while reducing errors and unnecessary transport costs.

Third-Party Logistics (3PL)

Space savings, efficiency, and speed are key competitive factors in third-party logistics. The bin shuttle system makes these easy to achieve. With significantly greater space efficiency compared to conventional storage systems, you can increase the profitability of your warehouse and serve more customers at the same time. The modular design of the system allows you to increase performance, capacity, or roaming capabilities. The result is high scalability and easy adaptability to new challenges - the ideal conditions for staying competitive in third-party logistics.

Technical Data

| Load types | Bins and trays of various materials (plastic, metal, etc.) |

|---|---|

| Format | Width x length: 600 x 400 mm, height: 120 mm or greater, weight: up to 50 kg |

| Dimension | Flexibly scalable. Maximum height: 26 m |

| Temperature range | 2 - 45 °C |

| Performance | Flexibly scalable. Up to 1,500 storage and retrieval operations per hour and aisle |

More Solutions from Kardex

Bin Conveyor System

Kardex offers bin conveyor systems as part of larger automated warehouse solutions. These conveyors help boost material flow, reduce manual bin handling, and optimize labor resources. The conveyors complement small parts solutions such as our miniload systems, bin shuttles, or the AutoStore system.

Kardex Control Center

Kardex Mlog’s modular software solution Kardex Control Center manages material flow and warehouse management processes faster and more efficiently with flexible modules for a solution that fits your warehouse management needs.